Cum voluturum eligis, materiae electio directe perficiet effectum, permanentiam et adiunctum volutorum. Inter commissimiores generas sunt volutae nylonus et volutae plasticae. Etiam si haec duo genera similiter videantur, distincta differentia materialis inter ea est. Hoc articulus praebet directionem de modo quo efficaciter discernere possis inter volutas nylonas et volutas plasticas.

1. Compositio Materialium

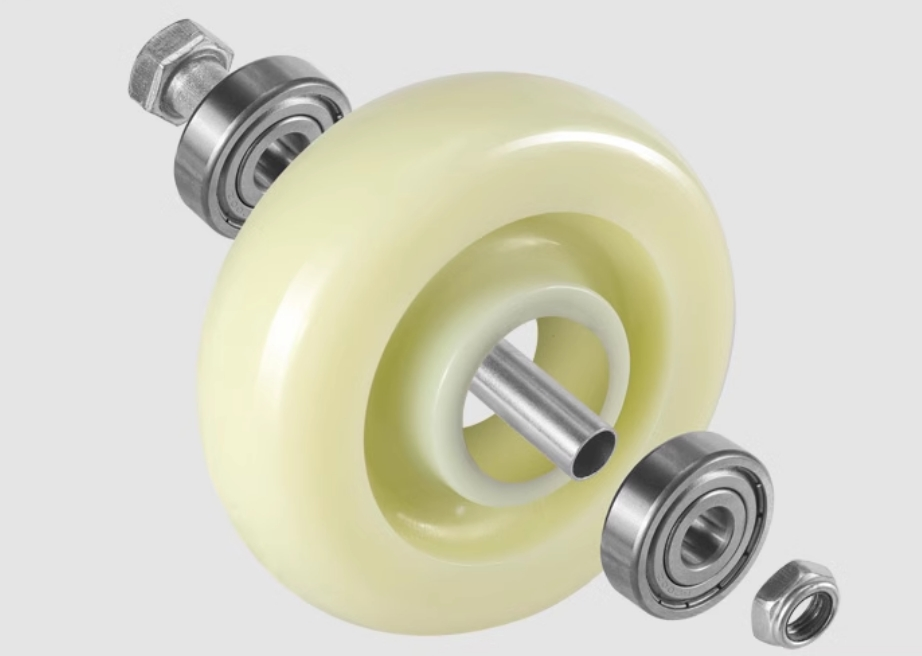

Rotuli e Nylon nylon est polymerus syntheticus, saepius polyamide (PA), notus propter egregiam resistenciam adversus usum, corrosiones, et vim. Processus fabricandi volutarum nylonarum saepe involvit injectionem formandi, quod solidam et durabilem rotam corporis efficit.

Rotulae plasticae : Plasticum est terminus latus qui communiter refertur ad varias resinas syntheticae, sicut polypropylenum (PP), polyethylenum (PE), aut polyvinyl chloridum (PVC). Hae materiae varie proprietates habeant, quod significat duritiam, robur, et costum rotularum plasticarum possunt multum differre secundum materiam usam.

2. Species et Tactus

-

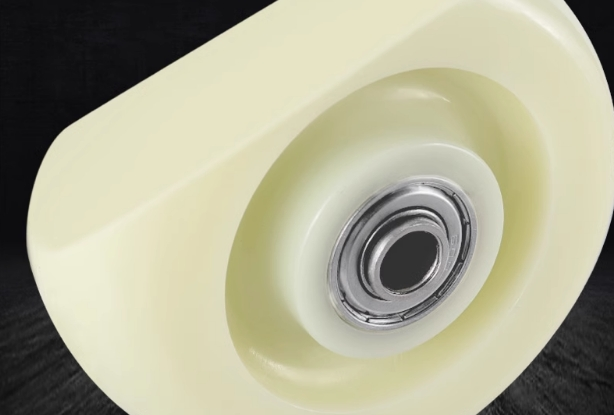

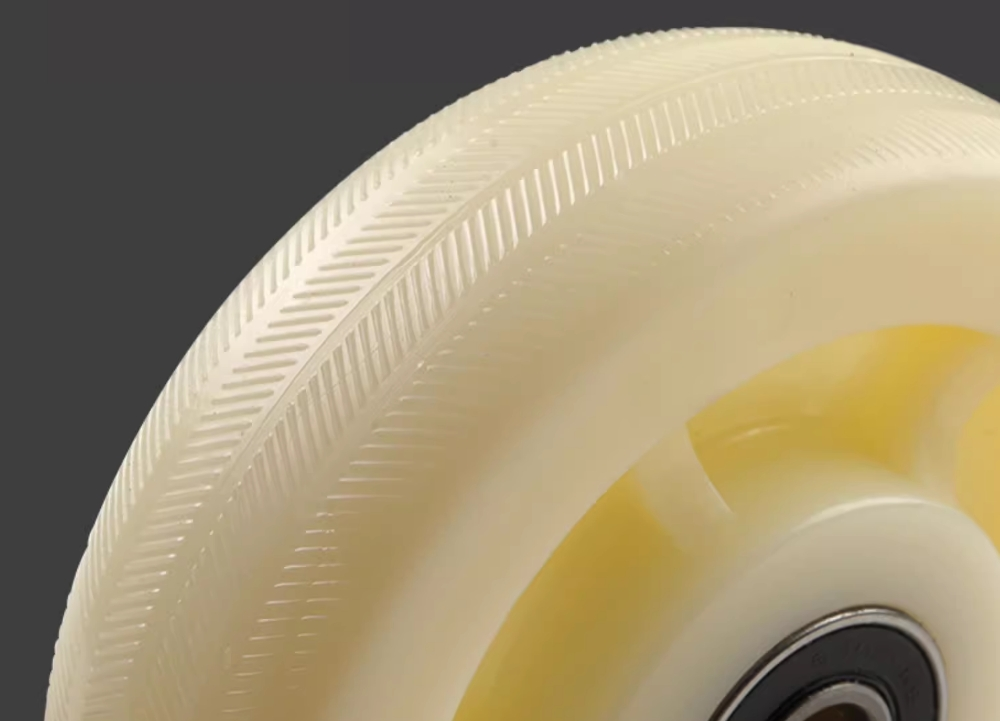

Apparentia : Rotulae nylonatae saepius finem nitidum habent, superficiem lenem, et sunt saepius nigrae vel colore tenebrico, cum minima deformatione. Rotulae plasticae, contra, possunt venire in variis coloribus, et lenitas superficiei potest multum variare, ostendens fortasse texturam asperam.

-

Sensus : Cum tangentur, rotulae nylonatae saepius duriores sentiuntur et quandam elasticitatem exhibent. In contrastu, rotulae plasticae molliores sentiuntur, praesertim illae factae ex polyethyleno aut polypropyleno.

3. Experientia Performantiae

-

Capacitas oneris : Rotuli ex nylo communiter maiorem capacitatem oneris habent, eos idoneos reddentes ad applicationes gravis usus. Rotuli plasticis possunt deficere in capacitate oneris, praesertim si ex plasticis mollioribus facti sunt.

-

Gerunt Resistentia : Rotuli ex nylo excellentem resistentionem usurae praebent, eos optimos facientes pro locis ubi usus frequens requiritur. Rotuli plasticis, comparatione, possunt inferiorem resistentionem usurae habere et vitam breviorem.

4. Adaptabilitas Environmentalis

-

Resistens Temperatura : Nylo bene operatur in ambientibus calidis et potest sustinere temperaturas altiores, dum alii plasti (veluti chloridum polyvinyl) possunt deformari aut deteriores fieri sub calore alto.

-

Stabilitas Chemica : Nylo bonam resistentionem oleorum et quorundam chimicorum habet, dum alii plasti veluti polyethylenum et polypropylenum non ita bene performant chimice, praesertim cum substantiis aggressivis exponuntur, quod senectutem et deformationem inducit.

5. Differenciae Pretii

Propter maiorem onerum productionis nylonis, rotuli nylon solent esse cariores quam rotuli plastici standardes. Consumptores possunt facere decisiones ex suis budgetis et usibus destinatis.

Summa

Etiam si rotuli nylon et plastici videantur similes primo intuitu, diligens observatio compositionis materialis, exterioris aspectus et tactus, experimenta performance, adaptabilitatis environmentalis, et pretii possunt iuvare ad distincte discernendum inter haec duo materia. Eligendo rotulis, usores debent considerare suas reales necessitates ut certum habeant optimam operationem et experientiam usoris. Intellectio harum differentiarum iuvabit in faciendo prudentioribus decisionibus tam in vita cotidiana quam in applicationibus industrialibus.