Scribere rigidum rotam caster pro tuo projecto potest videri formidolosum. Posset te tentare facere listam omnium alternativarum ibi, sed si hoc facis, risicum relinquentis et intercludendo fluxum cogitationis tuae. Sed ne timeas! Taiyada iuvat te intelligere quomodo eligere rectas rotas pro tuo typo. Hic te perducemus per selectionem perfectarum rigidarum rotarum caster in paucis facilibus gradibus.

Quomodo Eligere Rotas Caster: Res Memorandae

Sunt paucas claves considerationes de quibus cogitandum est antequam mergaris in electionem rotarum pro tuo projecto, tamen. Quod scire oportet hoc est:

Limitatio Ponderis: Primum, oportet te determinare quantum pondus portabitur ab rotis. Hoc valde importans est, quia hoc te iuvabit eligere recte magnitudinem rotarum quae possint tute accommodare pondus. grandes rotae mobiles utere rotis nimis parvis aut infirmis onus portare cito conteri possunt. Cura etiam pondus limitare priusquam electionem tuam facias.

Material: Rotae mobiles ex variis materialibus conficiuntur, et hoc quoque eorum operationem afficit. Pro machinis aut instrumentis gravioribus,elige rotas ex fortibus materialibus sicut ferrum aut aes. Haec materia dura in locis asperis permanere potest. Tamen, si leviorem laborem geris, rotae ex plastico aut caucho praeferantur quoniam magis mobilis sunt.

Ubi eas usurpabis: Item est considerandum ubi rotae utendae sint. In loco umido aut oleoso, necesse est ut rotae quae non praecipitent aut rubescant. Ferrum inoxydabile aut cauchum specialiter factum bene fungitur in huiusmodi loco. Illa diu durant etiam in conditionibus quibus operaris.

Optimae Rotae Fixae — Guida Compratorum

Cum terra praeparata sit, hoc est quod considerandum erit in electione rotarum pro tuo opere. Ecce aliqua utilia consilia:

Accipe magnitudinem: Primum oportet accipere magnitudinem, deinde castor wheel replacement scire oportet quam magnam rotam desideras. Metis altitudinem et latitudinem eius rei cuius superficie uteris rota. Hoc facilius faciet ut recte positis rotis onus excedens sine difficultate portetur. Accipere rectam magnitudinem valde est importante pro operatione et securitate.

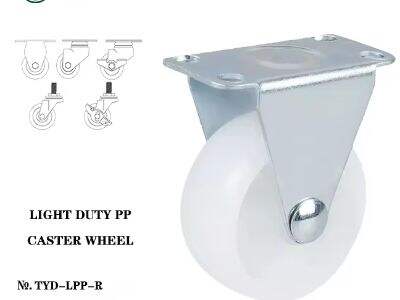

Genera rotarum caster: Sunt multa genera rotarum caster, et unumquodque genus ad certum propositum designatur. Rotae versatiles possunt in omni directione rotari, eas versatiles et usui facilem reddentes. Rotae fixae tantum antecedunt vel retrocedunt, quod est utile in directa via. Rotae cum directione solummodo in illa directione moveri possunt, itaque optime eligantur secundum tua desideria.

Genus Superficiem: Cogita super genus superficiei quam rotae volubiles transibunt. Maior set rotae in materia molli, ut est caucho, melius sunt si superficies est aspera vel inaequalis. Hae rotae melius transgredi possunt super tuberositates et fissuras. Tamen, si superficies est levis et plana, potes eligere materiales duros, ut ferrum, quod tibi nullam molestiam dabunt.

2 Commentarii pro Consiliis ad Eligendam Robustas Rotas Volubiles

Vis habere rotae quae diuturne permanebunt et sunt durabiles. Ecce pauci consilia ut te incipere faciant hoc facere:

Investe in Materia Optima Qualitate: Semper opta rotae in materia optima qualitate. Hoc industrialia volubilia eos capacitate ut gravia onera supportent et securitatem praebet ut diutius permaneant quam variantes viliores. Cum rotae expensivae esse possunt, emere bonas rotae te faciet pecuniam economizare in longo cursu quoniam non erit necesse eas tam frequenter emere.

Pondus aptum: certiora facito rotae habeant capacitatem oneris convenientem pro tuo opere. Si rotae eligis quae non possunt onus portare, cito deteriorentur et etiam frangantur possunt. Semper melius est esse tutum quam eum qui paenitet, itaque sive pondera specifica inspicienda sunt!

Frenos: Mag rotae frenos lenes sunt et optima electio fiunt. Nunc, si aliquid movis, frenos tibi adiuvat rem, quam moves, in uno loco tenere et non sinere illud volvi ubi non vis. Hoc specialiter utilis est si in declivio operaris aut rem securam habere pro alia causa oportet.

Sunt pauci errores communes quos facere non debes cum rotae caster legiferant. Ecce aliquot meminisse:

Selectio nimis parva: Rotae quae non sunt adaequatae oneri quem portas. Hoc errorem citius adficiat frictio frenorum etiam fracturas, quod periculosum est. Cura ut rotae sint adaequatae magnitudine propter usum.

Materialis inappropriatus: Cura ne legas rotam factam ex materia inidonea pro tuo ambiente operationis. Usus materialis incorrecti faciet rotae rubescere aut fracturas super tempus. Eligere materiam loco ubi erit usus et optimos effectus.

Cursus rotarum: Item cura pensare ad cursus rotarum! Hi componentes coniungunt rotas ad rem quam portas. Si onus sustinetur a cursu infirmo, rota fortasse non bene operabitur. Est importante ut cuncta partes simul tute operentur.

Ita, eligere rectas rotas fixas est confusum exercitium pro tuo projectu. Sed ne timeas — per intelligendum principia aspectus considerandos, potes invenire ideale coniunctum rotarum pro te. Intrare Taiyada ut tibi praestet auxilium in hoc universo processu cum aliquot optimis rigidis rotis caster quae sunt durabiles et in perfecta forma! Sume tempus, fac quaestionem, et fac optimum iudicium pro tuo projectu.