How to Choose the Right Casters for Your Needs?

Casters play a vital role in modern life, from office chairs to industrial equipment. Choosing the right casters not only enhances the user experience but also ensures stability and safety of the equipment. This article provides a detailed guide on how to select the appropriate casters based on your specific needs.

1. Understand the Basic Types of Casters

Fixed Casters: Fixed casters can only move in one direction, making them suitable for applications where directional stability is required or where movement is infrequent. For instance, fixed casters are commonly used on filing cabinets or some stationary equipment.

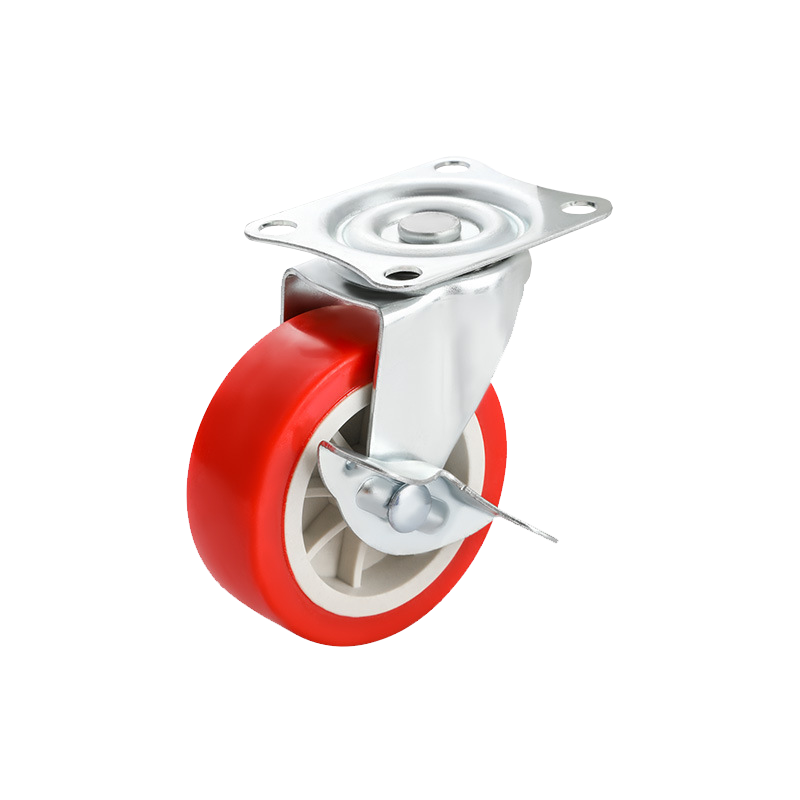

Swivel Casters: Swivel casters can rotate 360 degrees, making them ideal for applications that require frequent direction changes. For example, swivel casters are used in office chairs, carts, and other equipment that needs to move flexibly.

Double-Wheel Casters: Double-wheel casters have two wheels side by side, providing greater stability and load-bearing capacity. They are suitable for applications requiring higher load and stability, such as large workbenches or industrial machinery.

Single-Wheel Casters: Single-wheel casters are suitable for lighter loads and simpler movement needs. They are generally less expensive than double-wheel casters but offer lower load capacity.

2. Determine Load Capacity

Calculate Total Load: When selecting casters, first calculate the total load they need to support. This includes the weight of the equipment and any additional load. Ensure that the casters’ load capacity exceeds the total load to ensure safety and longevity.

Choose the Right Material: The load capacity of casters is influenced not only by their design but also by the materials used. Common caster materials include plastic, rubber, and metal. Plastic casters are suitable for light loads and dry environments, while rubber casters are ideal for applications requiring quiet operation and shock absorption.

3. Consider the Type of Floor Surface

Smooth Floors: For use on smooth floors, such as tiles or hardwood, choose casters with soft wheels to minimize damage to the floor and reduce noise.

Rough Floors: For rough or uneven surfaces, select durable casters, such as those with steel wheels or larger wheel diameters, to improve mobility and stability.

4. Consider the Operating Environment

Wet or Chemical Environments: If casters will be used in wet or chemical environments, choose materials that are corrosion-resistant and chemically resistant, such as stainless steel casters or chemical-resistant plastic casters.

Temperature Extremes: For high or low-temperature environments, select casters made from materials that can withstand extreme temperatures. For instance, high-temperature casters are suitable for hot factory environments, while low-temperature casters are appropriate for cold storage areas.

5. Determine Additional Features

Brake Function: For equipment that needs to stay in place, choose casters with brakes to prevent movement and ensure stability during use.

Self-Locking Feature: Some casters come with a self-locking feature that automatically locks the caster when not in use, ideal for applications that require frequent stopping.

Shock Absorption: For applications needing shock absorption or noise reduction, choose casters with shock-absorbing features to minimize vibration and noise, enhancing user comfort.

6. Check Installation Requirements

Mounting Holes: Different casters have various mounting hole configurations, so ensure that the caster’s mounting holes match those on the equipment.

Mounting Type: Casters can be mounted in different ways, including plate mounts and bolt mounts. Choose the mounting type that fits the design and requirements of the equipment to ensure secure installation.

Summary

Choosing the right casters involves considering multiple factors, including caster type, load capacity, floor surface, operating environment, additional features, and installation requirements. By carefully analyzing these factors, you can ensure that the selected casters perform optimally in practical applications, enhancing equipment performance and safety. This guide aims to assist you in making an informed decision when selecting casters.